Fermentation and Fire Detection System at Van Egmond Potting Soil Certified!

Van Egmond Potting Soil recently received certification for their fermentation and fire detection system. This is remarkable, as certification body VdS had never before issued a certificate in the Netherlands for a system that detects fire and/or fermentation using thermal cameras.

Following a devastating fire over two years ago, Van Egmond had to build a new production facility. “Our insurer required a fully monitored fire detection system according to NEN 2535 standards, such as an aspiration system,” explains Rob van Egmond (Project Manager at Van Egmond Potting Soil). “However, due to our previous fire experience, we knew that an aspiration system wasn’t a suitable solution for us. The hall is tall, which means it always takes time for the aspiration system to detect a fire. Moreover, it’s dusty, and the hall is open, causing constant air movement and – depending on weather conditions – humidity.” “These aren’t ideal conditions for an aspiration system,” confirms Erik Poulussen (Account Manager at Mactwin). “We wanted rapid detection and a truly reliable solution. This is typical Van Egmond mentality! We’re doers and a bit headstrong,” Rob van Egmond jokes. “In this project, all parties demonstrated their can-do attitude.”

At the official certificate presentation, we’re sitting with three proud stakeholders: Rob van Egmond (Project Manager at Van Egmond Potting Soil), Marcel Ruesink (Director of VdS Netherlands), and Erik Poulussen (Account Manager at Mactwin).

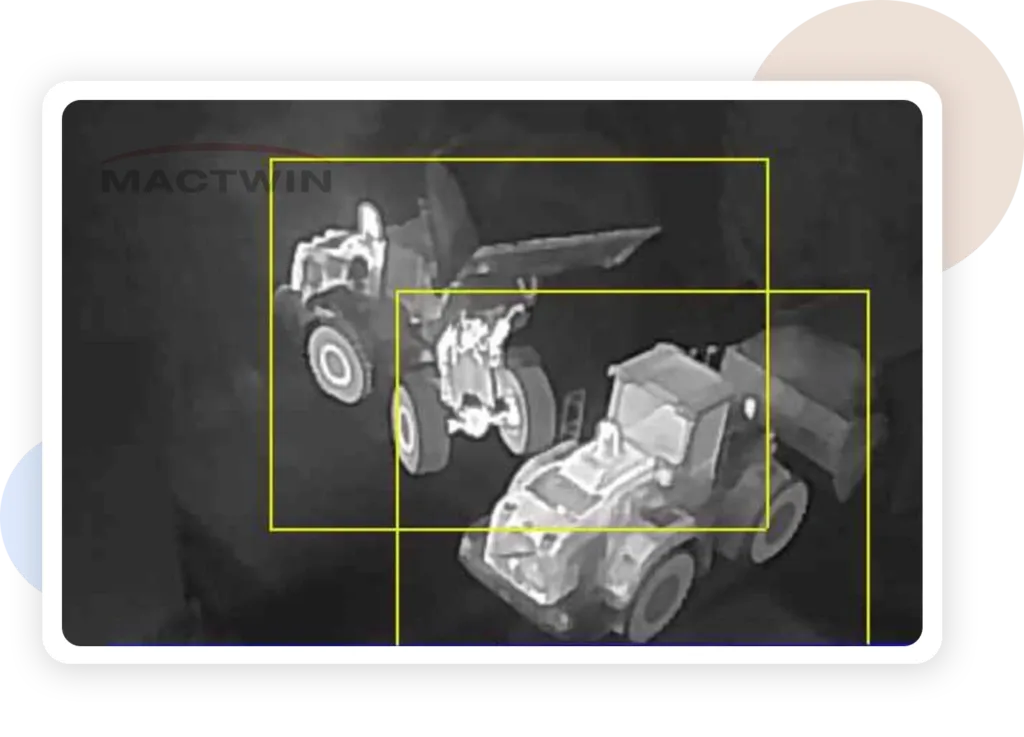

In the camera footage, vehicles are marked with a yellow frame. These are excluded from temperature measurements as they always emit heat.

Correct Camera Positioning

In search of a better solution, Van Egmond found Mactwin. Erik Poulussen: “There are now 38 thermal detection cameras continuously measuring temperature throughout the hall and monitoring the motors and conveyor belts of the mixing lines. With this type of solution, it’s primarily about the correct camera positioning and, of course, quality cameras. There is a lot happening in the production hall. There are piles of raw materials, conveyor belts, mixing machines, and wheel loaders and forklifts moving around. Fire risks are present everywhere, and the art is to identify and locate them. So that the cameras measure the temperature precisely at those locations. At the same time, a hot exhaust from a wheel loader must be excluded. We therefore had to be very precise.

“The result is indeed impressive. We are very pleased with this installation, which now runs entirely fault-free (without false alarms). When a fire alarm is triggered, camera footage is immediately sent to the control room. This allows them to properly assess whether there is actually a (developing) fire. Only then do they forward the alert (with Priority 1) to the fire department. I have complete confidence that we now have a future-proof solution. And I often think: if we had had this system earlier, things would have turned out very differently 2 years ago.”

Rob van Egmond

Project Manager at Van Egmond Potting Soil Amsterdam

“This is the first time we’re certifying this type of solution. I find it very innovative, but more importantly, well thought out and reliable. This was also evident during the installation testing. My colleagues tested all 38 cameras with a test plate at the least favorable distance from the cameras. They all passed with flying colors! I am therefore very confident in presenting this certificate to Van Egmond.”

Marcel Ruesink

Director of VdS