You do not want to turn your building into a dark bunker. Openness and transparency are very popular with architects and your employees; daylight and views contribute to their well-being. But does the nature of your organization also bring significant risks, such as explosions? What are the possibilities for explosion-resistant walls and how does this relate to the resilience of the entire shell of a space? With the right assessment of risk scenarios, design, and layout of your building, it can be determined what (im)possibilities exist. Daylight and sufficient shielding against contact or cutting charges are usually not feasible (or affordable). In cases of a distant explosion, explosion-resistant glass and frames make your windows a robust part of your structural security.

All about Explosion-Resistant Windows

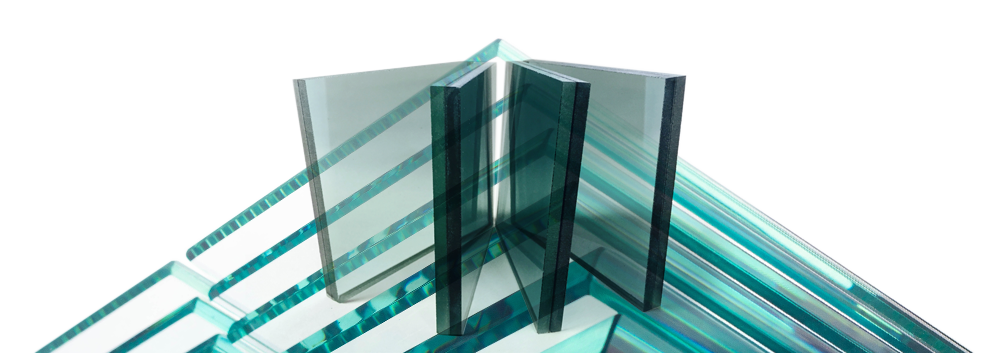

Explosion-resistant windows consist of frames with glazing specifically developed to withstand the pressure waves of an explosion. This glass consists of various glass and plastic layers and is often used in buildings with an increased risk of an attack or ram raid (politics, justice, places of worship, jewelers, etc.), or for example in industrial environments.

The frames of explosion-resistant windows are anything but standard. There is much involved in making a window explosion-resistant. Consider, besides the glazing, the dimensions, panel division of the facade element, building physics performance, etc. Everything is important for the resistance class.

In many cases, we make the windows not only explosion-resistant but also bulletproof, fire-resistant, and burglar-resistant. With our advice, you are always assured of the best price-performance ratio. Contact us now.

Variants of Explosion-Resistant Glass

It is important to note that glass types, in addition to the available resistance classes, can be further divided into splintering and non-splintering – recognizable by the additional designation S for splitting (not safe) and NS for non-splitting (safe). With splinter-free (NS) glass, no or limited splinters are released on the protected side, so that people directly behind the glass are as protected as possible.

Glazing is constructed with different layers. Glass with PVB interlayers and/or in combination with polycarbonate layers. Polycarbonate makes glazing thinner and lighter but is also more expensive.

Standardization of Explosion-Resistant Windows

For explosion resistance of windows in distant explosions, standards have been established. The explosion-resistant glass we use is extensively tested with, for example, a shock tube, where the glass is exposed to the equivalent of various amounts of TNT detonated at 35-50 meters. Or in a field test, where a quantity of TNT is detonated at a certain distance in the open air.

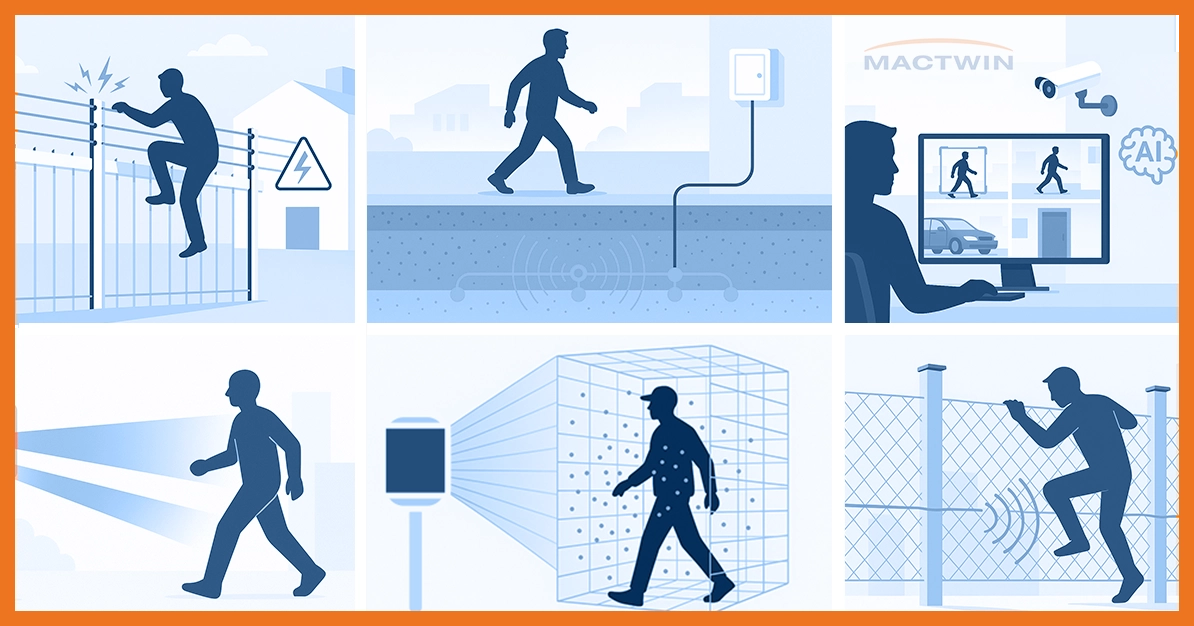

There are no standards for resistance and protection against contact and cutting charges that are directly placed on facade elements such as doors and windows, but also walls. Mactwin has gained experience with practical tests to investigate the effect and failure progression to implement the right measures.

For distant explosions such as car bombs and industrial explosions, standards have been established. For example, the European standards

Resistance Class of Explosion-Resistant Windows

For the definition of resistance classes, several factors are important; consider the size of the glazing used, distance from explosive to target (Stand-off), amount/weight of explosives, peak pressure, impulse, and duration of the impulse. Also, the degree of splinter formation on the safe side of the glass and the extent to which, for example, a window disintegrates under pressure are determining for the safety level.

Depending on your risk profile, we choose the resistance class that your situation requires and that fits your ambition together with you.