Technological developments are progressing rapidly today. This is also true in the field of blast resistance. Increasingly, we see new technology that potentially makes the world a little safer. However, with blast resistance, the risks are so high that an ill-considered choice can have catastrophic consequences. Our Product Management department closely monitors new developments and thoroughly tests these innovations before deciding to implement them for a project. Below you will find an overview of blast-resistant innovations that have passed our tests and which we fully endorse.

SecuraBlinds – Blast-Resistant Blinds

To secure (existing) windows, Mactwin has partnered with the English company Abbey Group to implement their SecuraBlinds, so-called blast-resistant blinds, in the Netherlands. SecuraBlinds look and can be used like ordinary sun-shading vertical blinds, which are commonly seen in office environments. However, these blinds also absorb the pressure wave of an explosion. The positive phase of the pressure wave pushes the blinds shut in a split second. The window on the outside may shatter into thousands of fragments, but the blinds keep all these fragments and other debris out. The SecuraBlinds are even strong enough to eject glass and debris outwards during the so-called negative phase of the pressure wave. We have extensively tested this with various amounts of explosive material. Even when detonating as much as 500 kilograms of TNT at a distance of 28 meters, the blinds fully absorbed the pressure and force of this explosion. These blinds are now being used in various locations in the Netherlands, in the financial heart of London, in the Middle East, and in conflict zones to protect government buildings, offices, and hotels against the effects of car bombs.

Blast Curtains

Where 'traditional' building materials like steel and concrete are not an option, there is now the possibility to implement a barrier in the form of a so-called Blast Curtain, or a blast curtain. These curtains are flexible and can be quickly installed temporarily. For example, in an industrial situation where maintenance is required in a hazardous environment: you can quickly shield your employees, and they can perform their work safely. The curtains can be wrapped around (high-pressure)equipment (to prevent projectiles in case of an explosion) or linked together with a frame. This way, any size can be achieved. The frame then works with a rail system, allowing a cabin or compartment to be created with automatic doors and roof. Blast curtains have been extensively tested to mitigate projectiles and hydrostatic pressure. Blast Curtains are widely used in the industry (petrochemicals, fracking, high-pressure) and in military environments.

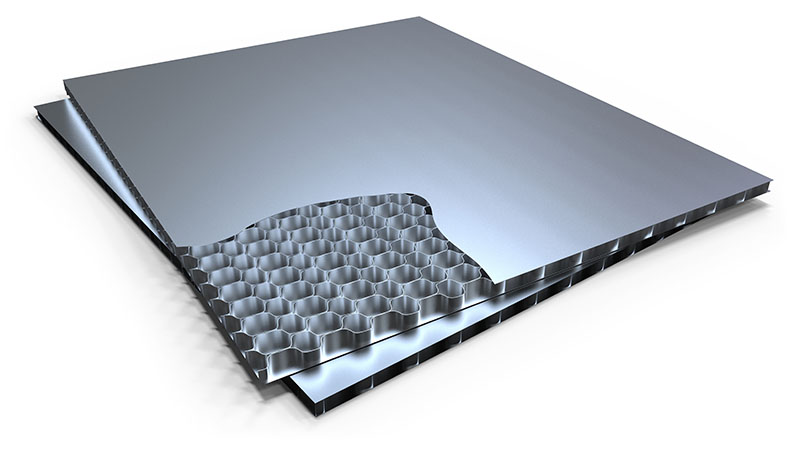

Composite Panels

Composite panels, or sandwich panels, are widely known from aeronautical and automotive applications. Lightweight composite material can achieve very high stiffness-to-weight ratios, making the material also interesting for blast resistance in situations where weight is a limiting factor. Specifically, Fiber Reinforced Polymer (FRP) sandwich panels have been extensively studied for their blast resistance. Regarding the core (the filling between the plates), there are various possibilities. These include cores with honeycomb structure, woven structure, cores with sand, cores with syntactic foam, and more. Depending on your situation, we would be pleased to discuss the options.

Mesh Nets

Many people know mesh nets from their application in tunnels, mining operations, and in mountains, to prevent falling rocks, superficial landslides, and avalanches. In motorsport, too, these strong steel mesh nets ensure that people in stands and the paddock are protected if a vehicle crashes. While these products are not new in the classical sense, their application for blast resistance is. The mesh net can be applied either within or against a wall, or in front of a wall, so that an explosive projectile cannot reach the wall and damage to the wall is reduced. Our specialists would be pleased to explain how we have implemented this solution in practice.

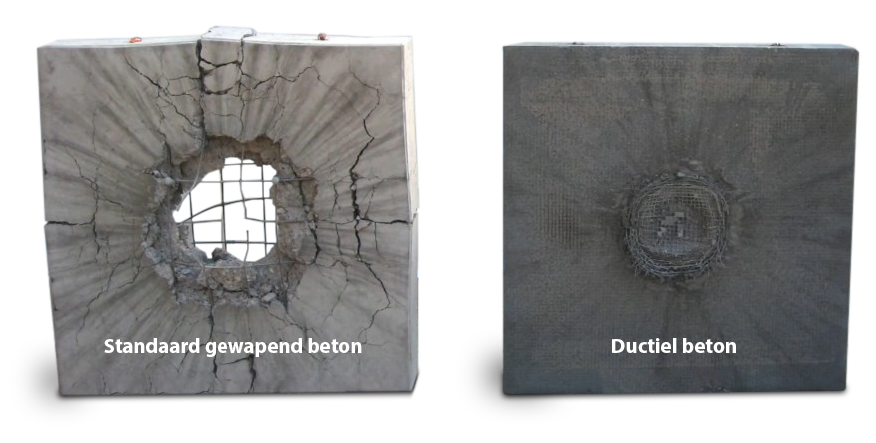

SHock-Absorbing Ductile Concrete

Ductile concrete already meets the highest security requirements with very minimal component thickness. The blast resistance of this type of concrete has been demonstrated in tests with contact charges. On standard reinforced concrete (RFC), the explosion caused complete penetration with additional fragmentation/projectiles, whereas the ductile concrete panel only showed an indentation on the front side of the slab, without fragmentation or projectiles. This technology is widely used in the walls of existing and new buildings. Due to the minimal thickness of the components, facade constructions are also possible. This building material already protects various vulnerable infrastructures such as government buildings, embassies, data centers, and nuclear power plants.

Prefabricated Blast-Resistant Solutions

For situations where fast and flexible (temporary) ready-made–– blast-resistant solutions are needed, Mactwin offers prefabricated gatehouses, guardhouses/police huts and strongrooms for ATM installations that can be placed, for example, in a shopping center parking lot. These ATM bunkers are demonstrably resistant to explosives and the impact of ATM bombings. Also, these types of products are widely used in constructions in the world's most hostile environments, such as headquarters, embassies, diplomatic missions, airports, vital infrastructure, and other iconic buildings. Are you curious whether these materials are suitable for your situation?

Elastic Concrete Blocks

These are comparable to regular concrete blocks made of cement and aggregate, but contain a proprietary material instead of stone aggregate. This allows the product to flex under pressure and dissipate the energy of a bullet impact or explosion, without internally pulverizing or crumbling. Thanks to its elastic properties, this concrete block can return to its original shape, maintaining structural integrity. These elastic concrete blocks can withstand the impact of a car bomb (Vehicle Borne Improvised Explosive Device, or VBIED) at close range.