A building is vulnerable to an attack with a vehicle or to vehicles that can place individuals over a barrier or onto a building. Vehicle deterrence keeps vehicles at a distance from the building. While you can add a moat or retaining wall to a fence to prevent a ram attack, this is impossible at a gate, as authorized vehicles must be able to pass. A barrier does not provide the resistance needed for a high-security area. An extra heavy gate might be an option, but if it truly needs to withstand a ram attack with heavy equipment, consider bollards or roadblockers. But where and how do you best deploy them?

All about Bollards and Roadblockers

Bollards

Bollards are steel anti-ram posts that have been recognizable in the streetscape for years. During the time when many jewelers were robbed, these were frequently used, and this has paid off. We now see innovation in aesthetics in this area; anti-ram posts designed as trash cans or as greenery. This places less emphasis on the risk of a robbery while maintaining effectiveness.

As you can see, with all the variables, it becomes challenging to determine exactly which bollards you need in relation to your risks. Our experts are knowledgeable about a wide range of Modus Operandi, as well as the possibilities and limitations in technology from abstract to very specific levels. We are happy to advise you.

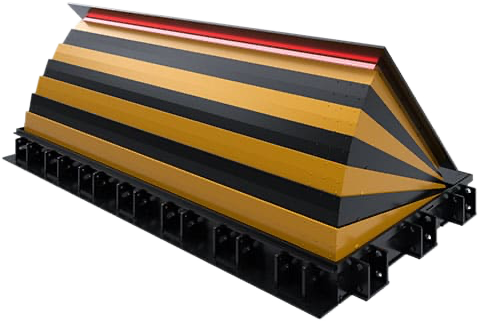

Roadblockers

In the case of high risk, a roadblocker is a very effective measure to deter vehicles. These wedge-shaped steel constructions with their recognizable signaling function are completely sunk into the floor and provide an obstacle-free passage if necessary, but in the closed position, high secure variants are even capable of stopping a heavy truck of 30 tons traveling at 80 kilometers per hour from ramming the roadblocker. Remarkably, they continue to function afterward to still allow emergency services access to the area behind the roadblocker. We frequently use roadblockers at cash centers, political or military government sites, and in vital infrastructure.

Do you want to know which type of roadblocker is the ideal security measure for your risks?

Standards for Bollards and Roadblockers

Standards have been established for crash tests on bollards and roadblockers. We use the standards for vehicle deterrence/crash tests (bollards, roadblockers, and barriers) PAS 68 and PAS 69. ISO/IWA-14-1:2013 is also used here. However, a standardized product says nothing about the quality of your overall deterrence. We ensure that all measures are built in balance and coherence with each other, so you can always provide the resistance and delay that are important for your organization. Do you want to know how we go further where the standard ends? Feel free to contact us.

Resistance Class of Bollards and Roadblockers

In the mentioned standards, a resistance class SR1-SR6 is often used. This provides a good guideline for the resources you use in your site security. However, it is advisable to always consider the purpose in relation to the resources. For example, an adequate stand-off zone between the various structural components is often more valuable than a well-standardized product on its own.

Depending on your risk profile, we determine the layering your site security needs together with you. We then adjust the resistance class per product to suit your situation and match your ambition.